I was bored over christmas so i thought i hit up something big on the car...First thing that came to mind beside a forge internal rebuild was an LSD...

I have lots of problems trying to put down 300nm when going around a corner :D

I would of loved to do a turbo upgrade but the dyno time costs about $800 and I don't want to spend that much coin considering i just did it a couple months back.

I started my research in Japan. I tried to track down all the info i can before i had the box split open in my garage and missing parts @_@

First part of business was the parts required

Worked out i needed

- the LSD and tapered roller bearings

- gearbox fluid GL4 75-90 (Quaife recommends standard gearbox oil, I managed to score Royal Purple)

- assorted pullers, tie rod separators, axle nut (32mm 6 sided socket - Impact!), female torx bits and assorted socket sets, spanners, geared spanners, hammers, crow bar, breaker bar, rattle gun, security bit set and torque wrench

- 2 jacks and 4 stands

I believe the female torx bit was a T12. I bought a set of them (ABW).

The LSD doesn't require shims or pretension settings. The bearing outer races are identical to the stockies and they are simply press fitted in. Biggest slut ever to remove

Some part numbers of the Ralliart Items

- Bearings which is RA930740K1

- Ralliart Gear Oil SAE/75W-140 Parts No.RA75140G11

Below is the Ralliart Part Number for the LSD - Z27AG -

Install Manual

RA250113S1 税込価格¥139,650 (¥133,000)

□ カム角度45°/15° 1.5WAY □ カムリング組替により、35°/15°

□ プレート10枚(フリクションディスク6枚、フリクションプレート4枚)

フロント機械式L.S.D.キット

COLT Ver-R M/T 適合

Never seen a gearbox internal...I found this little one of the Evo X DOG TYPE GEARBOX INTERNAL KIT RA250186N1

>>>

Cusco Part Numbers

LSD 440 C15 - Mitsubishi - Colt Ver. R - Z27AG - Front - 1&1.5 Way Model - 1.5 Way

LSD 440 F -Mitsubishi - Colt Ver. R - Z27AG - Front - 1 Way

Why i went Quaife over the Cusco/Ralliart model?

Clutch style units require a special oil as well as much more regular oil changes and i got the Quaife at a really good price :)

Where do i start?

1) I started with something simple, pressing on the bearings on the LSD. I couldn't find a bearing press and someone willing to help so I attempted it the old fashion way. I found that some people prefer this way so you can control it better.

I used a 32mm socket on top of a 34-36mm washer (i think) to tap on the bearings.

Use a bigger socket it you have one 32mm was my biggest ;)

NOTE: bearing and outer race are matched! do not mix them up and mark them.

2) Need to remove the axles from the gearbox. To do so you need to remove your rims, drop the gearbox oil, remove the axle nut (32mm) remove the tie rod from the hub and brakes.

You will also need to remove your brakes and rotors. Hang the caliper from the springs so no weight is on the brake lines.

To remove the tie rod a handy tool is a tie rod separator see right.

There are multiple types this is one of them.

To remove the gearbox filler/drain plugs you need a hex bit 5/16 i believe was the size.

It is worth while buying a M18x1.5mm brass fitting for the filler hole with a right angle bit so you can fill it up from the top of the engine bay anytime (I have completed this side project).

Then you remove your suspension to hub bolts (2 of them)...I marked all bolts, well tried to.

Once the hub is hanging freely you might have to smash the axle end to release it from the hub bearing.

Once it is released you can remove your hub assy or just leave it hanging.

Dont do what i need and get impatient and use a tierod splitter bar, you just break shit (fail @_@ )

If you want to remove the hub assy spray the lower ball joint with CRC then use the ball joint/tie rod separator.

I removed the stock sway bar bolt also.

3) Driver side axle should come out easily there is no circlip holding it in apart from a 2 bolt bracket.

I have a after market front pipe that was able to stay on the hole time. The stock one might get in the way and may need to be removed. The passenger side axle might be a bitch because it has an internal snapring/circlip...so you need to wedge something between the gearbox and the cv joint/bearing thing.

Try not to damage the inner axle oil seal when removing the axle...Do this by pulling it straight out slowly without hitting the sides. Otherwise you have to replace it like I did. Which is fairly easy.

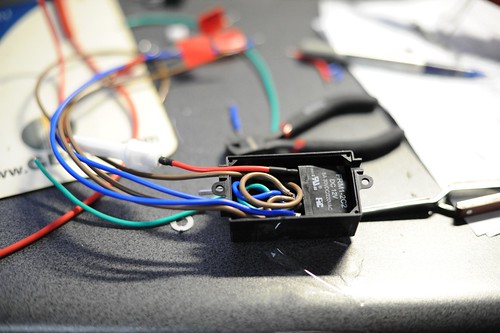

4) Other things you need to remove are battery, airbox, clutch master cylinder and starter motor. Various bolts on all of them, nothing to special. Also need to remove the clutch cover (that's what i call it, no idea the real name)

Those 4 red bolts and 2 others hold on the clutch cover thing (right).

Remove the black thing is the clutch master and the other black thing is the starter (above right).

5) Remove all the stuff in the way of the gearbox top side. I removed the battery tray and some of the intake pipes. There are 3 engine mount bolts you need to take off. Also another 5 bolts holding the gearbox to the engine.

Some are in stupid places a long extension and universal joints will help or a wobble bar. You still have to remove the gear linkages with a flat head screw driver will help to pop them off. Try not to damage them.

best to remove the 5 gearbox screws before the engine mount bolts.

Don't worry it wont drop, it is sitting on the crankshaft spline. Now the gearbox should come free with some movement. Try to break the seal on the bell housing.

From now on things get tricky. Dropping the gearbox off the spline @_@

We used two jacks to wiggle the engine up and down to get it to fall out. Do get an extra set of hands!!!

So by lifting the engine up (use a piece of wood between the oil sump and jack for protection) and down you need to be able to clear the gearbox off the side intrusion bar/car frame?

Clutch cover and front pipe (right)

basically a big sharp hook that hooked the inner lip so you can pull it out

basically a big sharp hook that hooked the inner lip so you can pull it out