Carbotech Performance Brakes

CT838/XP8

CT530/XP10

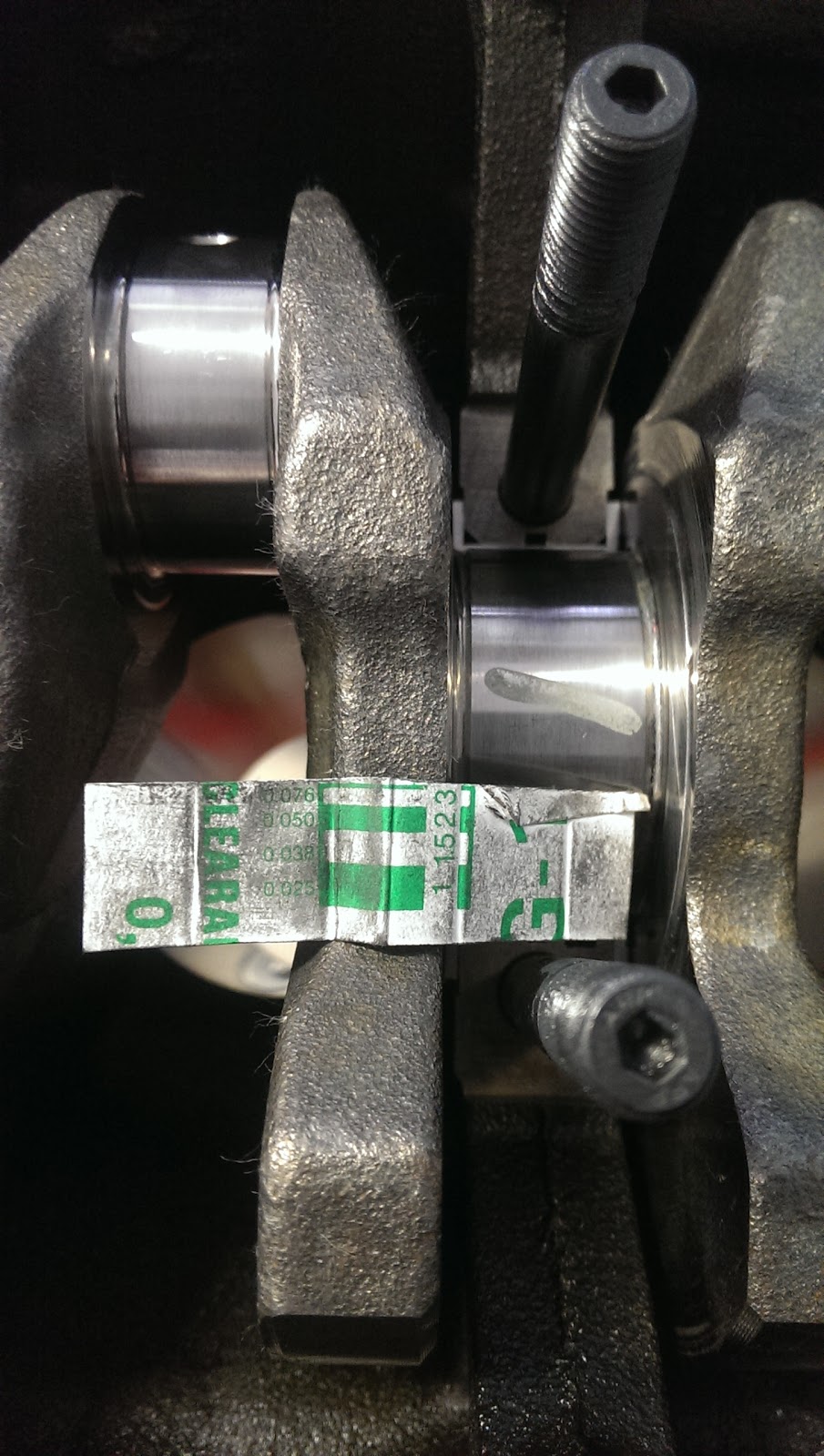

ELIG RS709 - Evo 1-3 - BP6039RS7

They are a semi metallic pad. Friction coefficient is around 0.5

Optimum temperature range 80-570C, maximum recommended temp 620C.

Pads research: /project-mu-or-carbotech-276mm-or-294mm.html

I will run these new ELIG pads with larger rotors /z27ag-rcolt-mr307282-with-294mm-discs.html

It will be hard to compare, but i aim for a 1:07 / 1:08 on the long track, previously I did a 1:09.

It will be a day time race, I am worried about the heat.

Last run on the Toyo R1R /no-limits-10012013.html

My first and last run on the Hankook RComps /no-limits-25042013-anzac-session.html

Actual times:

Long Track - 5 Laps - Fastest was Lap 2 - 1:09.9469 - Split - 0:07.2743

Short Track - 10 Laps - Fastest was Lap 7 - 0:58.1755 - Split - 0:04.3635

My Previous pads have included:

EBC Green :( > Overheated and cracked up

QFM A1RM :) > Good value for money

XP8 :)

XP10 :) Looks like it went really well.

Carbotech XP8 > Had fade once i dropped into sub 60sec laps

A high torque brake compound with a wide operating temperature range of 200°F-1350°F+ (93°C to 732°C+). Carbotech™ XP8™ is the first of our racing compounds. Good initial bite at race temperatures, high coefficient of friction, excellent modulation and release characteristics. Extremely high fade resistance and very rotor friendly. Excellent as a front brake pad for lighter applications weighing around 2,400lbs or less. Perfect for track day use with any tire and can still be driven safely to and from the track. Carbotech™ does NOT recommended XP8™ as a daily driven street pad due to elevated levels of dust and noise. Carbotech™ XP8™ is a great compound on the front & rear of most open wheel and sports racers.

Carbotech XP10 > No issues, but I now run a 58sec lap & want more bite

When Carbotech™ unleashed the XP10™ to the general public it was an instant success. XP10™ immediately gathered multiple regional, divisional, and national championships. The XP10™ has a very strong initial bite friction material with a coefficient of friction and rotor friendliness unmatched in the industry. Fade resistance is in excess of 1650°F (898°C).

< after two track days and road km

Due to the high level of friction and bite, this material is recommended for cars weighing around 2,900lbs or less. XP10™ still maintains the highly praised release, excellent modulation and rotor friendliness that have made all Carbotech™ compounds so successful. Carbotech™ XP10™ is not recommended as a daily-driven street pad due to possible elevated levels of dust and noise.