Doing some research on making a oil relocation kit + oil cooler

The colt can use various oil filters e.g.

Ryco - z411, z142a, z436

all have a seal diameter of 66mm and the same thread so should fit.Mitsubishi genuine oil filter, part number: MD356000

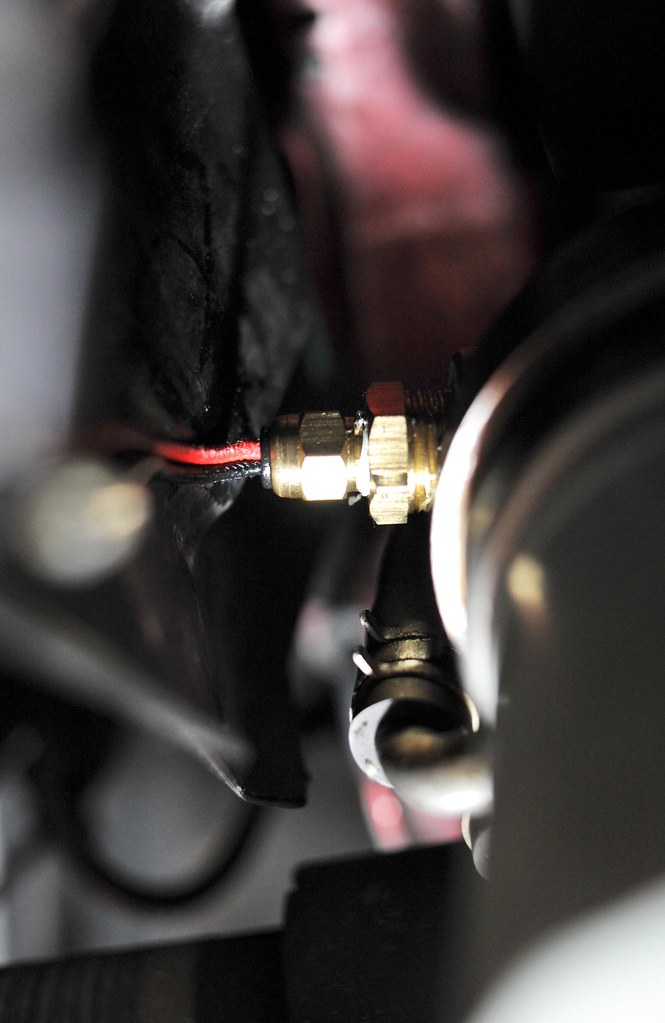

Took a photo when i was removing the light weight under drive pulley

The z142a is very short, so you don't have to worry so much if you have a lowered car ;)

Plan is that because the evo 9 and other evo use a similar oil filter or can use this one i believe the oil water block should also be interchangeable :)

I am looking at investing in an oil relocation block for an evo and testing it on a colt.

Our water block oil cooler is a M20x1.5mm still need to rip it off and check the top threads.

looking again at the whole oil cooler scene after seeing some cool oil breather/catchcan systems incorporating the PCV valve and the breather.

therefor getting less blow back and oil residue in the intake plenum

so one of the kits i been trying to understand is the whole oil relocation unit + oil cooler

- it starts at the oil relocation adapter [replaces the oil filter original location mount/assembly]

- engine out goes to > core in

- core out > filter in

- filter out > engine in

One of the threads i found use an inline thermostat from Greedy.

This allows the oil to heat up quickly.

another style is where the oil filter relocation block has 2 sets of in and outs

- 1 output goes to the filter

- 1 output goes to the oil cooler

- 1 input comes from the filter

- 1 input comes from the oil cooler

this style can use an oil termostat within the relocation block

the YR advance unit i read about does something similar minus the oil filter relocation unit

it replaces the stock water cooled oil element thing for a billet aluminum black with a thermostat inside

it has oil out and oil in to connect the oil cooler.

http://www.yr-advance.com/colt/gazou/colt064.jpg

http://www.yr-advance.com/colt/gazou/colt065.jpg

http://www.yr-advance.com/colt/gazou/colt063.jpg

http://www.yr-advance.com/colt/gazou/colt061.jpg

Mocal thermostat oil filter-to-engine sandwich plate.

Another Greedy style i have seen is where a relocation block is mounted on the engine

- engine out goes into the oil filter

- oil filter out goes to the oil cooler

- oil cooler out goes back to the oil filter relocation block and through to the engine

Basically the oil filter relocation block has 2 x in and 2 x out

I assume it is getting filter on the oil engine out and not the oil return.

Wouldn't want and particles going into the oil cooler.

MODEL MMOC-U (Silver, non-thermo), MMOC-UT (Silver, thermo), MMOC-UBK (Black, non-thermo), MMOC-UTBK (Black, thermo)

CORE 12.91" x 2.81" - THICKNESS 1.97"

INCLUDES

(1) - 10 Row Oil Cooler (Silver or Black)

(1) - 4ft 9in Stainless Steel Braided Hose w/ -10AN fittings -- One straight fitting and one 90 degree swivel fitting

(1) - 4ft .75in stainless Steel Braided Hose w/ -10AN fittings -- One straight fitting and one 90 degree swivel fitting

(1) - M20 Thermostatic Sandwich Plate (Non-Thermostatic Available)

(2) - -10AN Fittings

(2) - Dowty Oil Seals

(1) - Large O-Ring

(2) - 1/8" NPT Allen Key Plugs

(2) - Sandwich plate adapters

DASHES

No dashes = M20 x 1.5 -- M20 x 1.5

2 dashes = 3/4" -16UNF -- 3/4" -16UNF

BRAIDED HOSES 4ft .75 inch & 4ft 9 inch

BRAIDED HOSE FITTINGS -10AN

SANDWICH PLATE FITTINGS -10AN

CAUTION

It is the installer's responsibility to check all thermostat plugs, NPT plugs, line fittings, and other connections to assure they are fully tightened before operating the vehicle. Mishimoto recommends that you check all connections at regular intervals, especially during the first few miles after installation. For additional technical information, contact sales@mishimoto.com.

INSTALLATION TORQUE SPECS

15-25 ft/lbs (operating range) for all straight fittings and banjo bolts. Do not exceed the maximum torque rating of 35 ft/lbs.

As you can see its not really a catch can @_@ I thought i try something different so I install an ebay oil/water air separator used in a compressor.

As you can see its not really a catch can @_@ I thought i try something different so I install an ebay oil/water air separator used in a compressor.