IMPORTANT

All wheels & wheel fixings must be installed by a competent individual with the necessary expertise to ensure that a suitable product has been supplied, and that it has been fitted correctly.

I will not be held responsible for wheels coming off, premature hub bearing damage and any other issues that could occur due to increased camber & fitment of this product.

Download Installer Guide Here: Shim Template Guide

1degree vs 1.5 vs 2

The Colt is wearing 2degrees. The right amount to stop scrub.

The items.

Remove:

1) wheels

1) wheels2) brakes calipers > rotor > ABS sensor

3) four bolt in the rear of the hub

U need:

- star bits, allows you to remove the brake caliper

- Thinks it's a 13mm and 15mm and six point star to remove brakes

- Wire brush

- Wd40

- loctite (blue)

- socket set

- open end spanners

- M10x1.5x30mm, i went slightly longer by 5mm (stock from memory is M10x1.5x25mm )

How to remove brakes (a video!):

/z27agrcolt-new-stud-and-how-to-remove.html

/rear-rotor-upgrade-p1.html

/rear-rotor-upgrade-p2.html

Background Information:

/rear-shim-rcolt-draft-design.html

/sending-shims-to-act-rear-torsion-beam.html

/fitting-camber-shim.html

Summary:

/camber-shim-flash-back-for-torsion-beam.html

Basically from no rear camber (stock is about 1ish) to 3 degrees of camber and 4mm of toe, I then used the shim rotation to almost zero the toe. From 4mm I went to 1mm.

Further Reading:

/wheel-alignment-notes-tbc.html

Start Now!

Using the right tools are important, an open end spanner holds the slide bolt from spinning as you take out with the holding bolt, 13mm.

Make sure handbrake is off, you may have to bash the calliper off the disc with a RUBBER HAMMER.

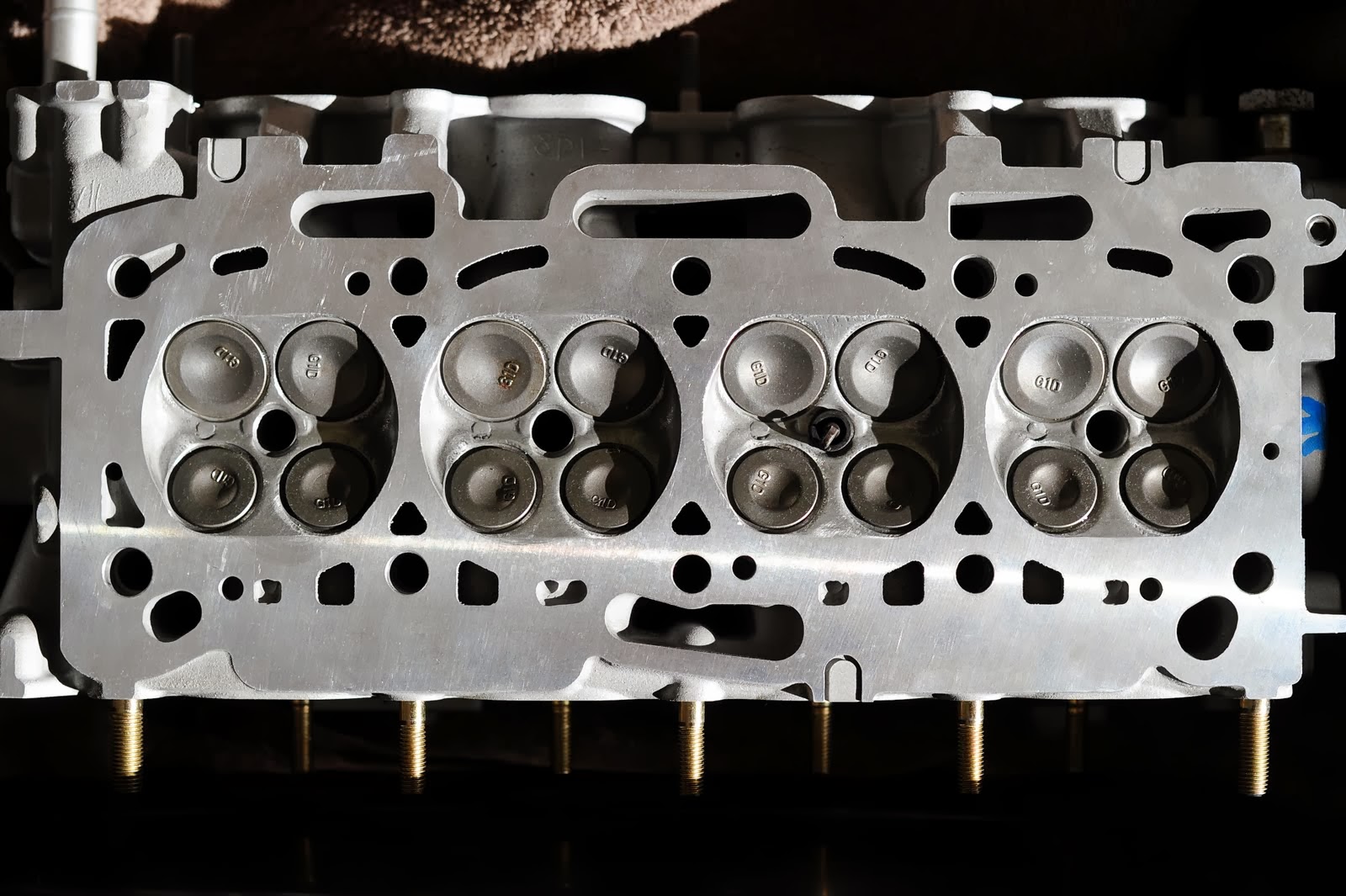

Then you need to remove with calliper mounting bracket with the torx 6pt stars, then the disc and you are left with this.

This is the rear of the hub, remove the ABS sensor first, the wire. Be delicate with it.

Then remove the four bolts holding the hub on, at this point i would snap off the outer heat-shield. Bend it back and forth like you would do with a coke can tab.

Clean surfaces, all mounting faces. Install shim (you can zero it later was the hub is almost tight, stop it slipping).

Bolting it all together, some people has a notch in there shim, you can use this to turn it with a flat head screwdriver, making sure its zero or where you want it to me. Half way in the notch should give about 3mm of toe. Max I would imagine give about 5mm.

More photos here: /fitting-camber-shim.html

Torque your bolts as tight as you can go. I would tighten each one up evenly, not just do one to the max then the next. Get them all biting into the hub so you know its sitting flat before you torque them.